In AutoCAD, you use reference files to share and convey information from different disciplines. This sometimes results in a populated drawing that sometimes causes issues with data integration as you may not always desire to see lots of colourful 2D lines to convey a simple message.

As you use Inventor as part of the PDM Collection, you are creating your individual parts and composing assemblies to convey design intent. You can insert AutoCAD Data into inventor, but again it has been seen that issues may arise with too much 2D/3D information all in one place.

How would you relay that 3D Model information back to the Design & Manufacturing Teams? Well, this is where the collaboration of various software is the key. Yes, you could send your Inventor drawings as AutoCAD Dwg’s to your contractors but sometimes information is Iost or corrupted in the data translation.

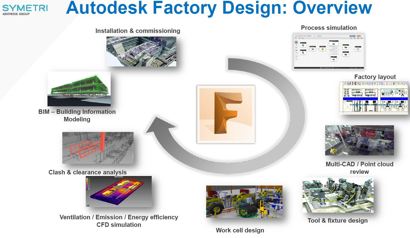

To enable software to perform best in its own domain, the Factory Design Utilities tools have been developed to enable the collaborative approach to work even smarter by allowing bidirectional workflow between 2D & 3D data and creating assets in inventor that would translate into 2D blocks in AutoCAD.