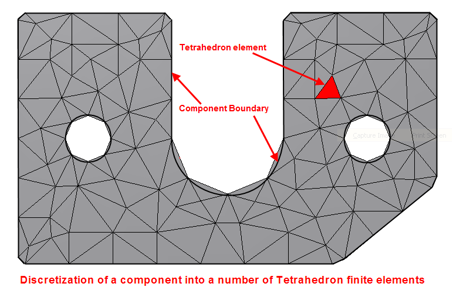

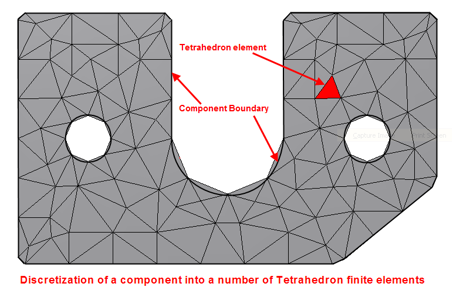

Stress Analysis by its very nature provides an approximation of the real-world problem by breaking it down into finite elements as shown below

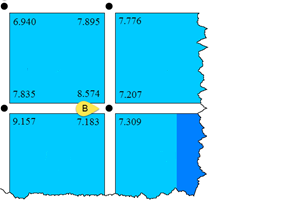

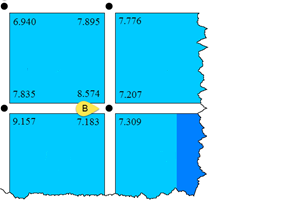

At each element corner (junction) there is more than one result from adjoining elements as illustrated below @ node B. Within Nastran In-CAD you can select whether you want to see the maximum value from all the adjoining elements or the average of all the values at the node.

So, if we look @ Node B we can have any of the following values displayed

Maximum option 8.574

Maximum option 8.574

Minimum option 7.183

Average option (8.574+7.207+7.183+7.309)/4 = 7.568

In an ideal world to obtain convergence in results, in addition to running analyses 3 times, we should expect the difference between minimum and maximum results to also be within 10% in the area of interest. The reason I mention the area of interest is that there may be scenarios when the location of the maximum or minimum value may not be in the same location most likely due to stress singularities. The difference between maximum and minimum results will reduce as the mesh size gets smaller and smaller.

I hope you find this article useful, in my next blog I will talk about centroidal results.

Maximum option 8.574

Maximum option 8.574