5 Ways Chaos Is Using AI to Transform Design Visualisation

Artificial intelligence is reshaping the way Architects, Designers, and Visualisation professionals bring ideas to life. Chaos, a global leader in rendering and visualisation technology, is at the forefront of this transformation. By integrating AI into its ecosystem of tools - Veras, Enscape, V-Ray, Corona, and Vantage - Chaos is streamlining workflows, accelerating creativity, and redefining what’s possible in design visualisation. This blog explores 5 ways Chaos solutions are supporting AI technology.

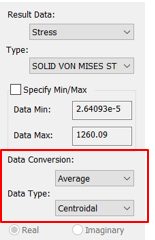

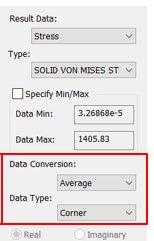

So, if we look @ Node C we can have any of the following values displayed.

So, if we look @ Node C we can have any of the following values displayed.