As a trainer my career transposed from being a Joiner many years ago into a Carpentry and Joinery Lecturer and then an AutoCAD Trainer. So when Inventor was introduced, I was keen to be on board with drafting and designing in 3D. When I was eventually introduced to Woodwork for Inventor, I was excited at the prospect of being able to bring my skills, workshop methodology, terminology and experience as a woodworker into Autodesk Inventor.

Many of my recent clients that are using Inventor are woodworkers, I have been developing training material for Woodwork for Inventor sessions for these clients and it has given me a great understanding of how we can marry the technology within 3D design and the traditional design processes in the woodworking industry.

Let’s look at an overview of the way Woodwork for Inventor is a great addition to the Inventor design tools.

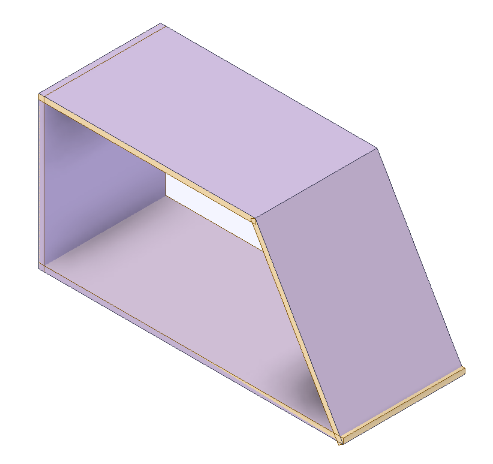

With a top down approach, the initial joinery design can be created in the form of an overall solid body, in the first instance. This is how Woodwork for inventor is quickly able to create board panels, the process is called skeleton dress-up. Here we can see an example of the simple solid body used as the skeleton with the dress-up panels in place.

We can then create the joints between the panels. We can define what each panel is made from, for example, laminated boards, solid timber or multi-layered boards. Adding edge veneers and lipping is also very straightforward.

The great benefit of using Woodwork for Inventor is that the design is parametric and therefore dynamically updates when changes are made. If for example, you change the height or width of the overall cabinet, Woodwork for Inventor would update all the relevant components used in the cabinet. Adding fixtures and fittings is extremely straightforward too, placing a handle is a matter of choosing the handle and aligning it to a work-plane and finished surface, and woodwork for Inventor will create the holes in the model as well.

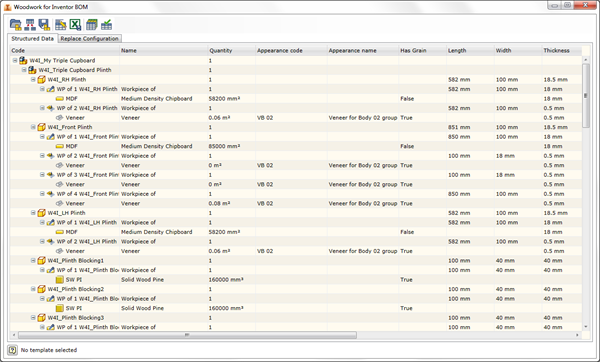

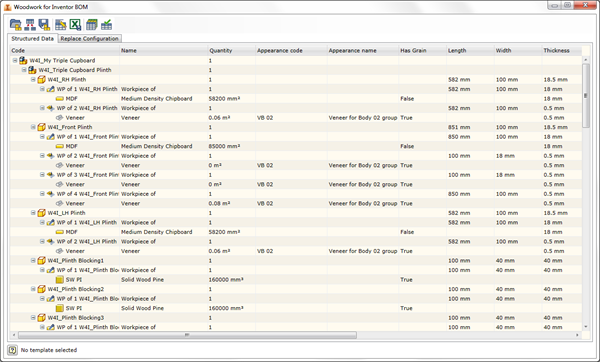

Having all the components monitored is not only a vast time saver but crucially it allows Woodwork for Inventor to create a list of all the components that make up the cabinet or counter being made. This list is called a bill of materials.

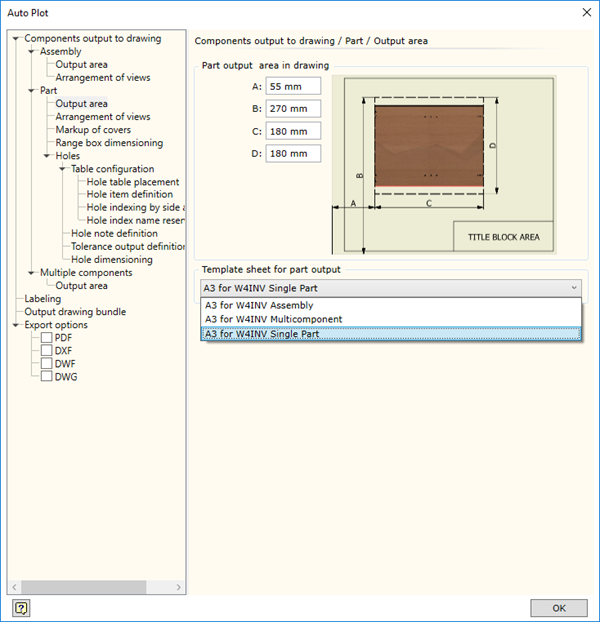

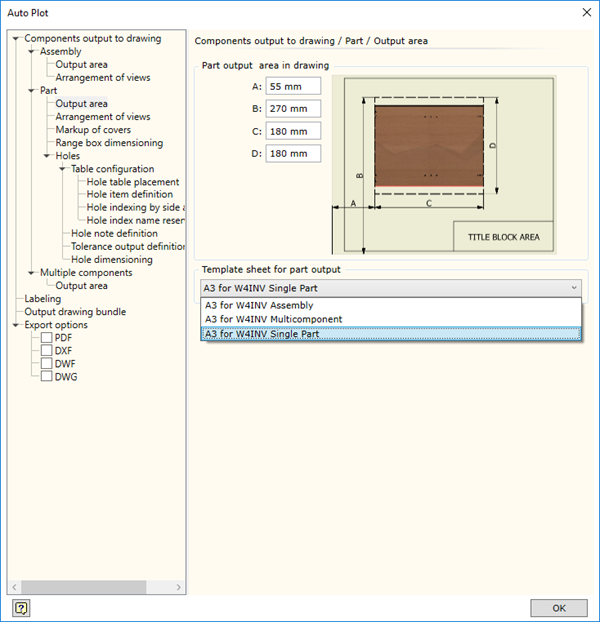

Taking this further still, within Woodwork for Inventor we can also create drawings of parts and include any data that we require to manufacture the parts. Holes grooves and other features can be described in an AutoPlot drawing.

The way that Woodwork for Inventor allows for design processes to take away the conversion of data from the designer and create that automatically is a huge benefit to the woodworking industry. I do remember as a joinery apprentice having to create drawings and cutting list of materials and a concept called setting out rods, this was a drawing on plywood that was full size to allow the marking out of components prior to machining. The development of CNC machines has greatly helped the machining of joinery components and Woodwork for Inventor has the ability through the CAM behaviour technology to send cutting instructions to a CNC milling machine.

Woodwork for Inventor is a very intuitive addition to Inventor. In my training courses I come across woodworkers who really find this process not just a great time saver but it greatly eliminates any costly errors. Woodwork for Inventor within the power of Inventor has advanced the woodworking industry.

My master craftsman taught me so much many years ago. I often wonder how he would comprehend the technology we have within Inventor and Woodwork for Inventor, I think he would be delighted.

For more information on Woodwork for Inventor visit our product page here.